RCC Column Process in Construction (2021)

What is RCC Column?

A column is the backbone of any constructional project, which is why it is necessary to understand the methods and techniques. An RCC Column is a vertical member that transfers the load from the beam and slabs onto the foundation.

The size of the columns, amount of cement, sand and mixture to be mixed, the number of steel bars to be placed, spacing between the stirrups is all mentioned within the structural drawing that is intended by the structural designer, as per the particular load on columns and considering the issue of safety.

An RCC Column is the vertical member that effectively takes load by compression. Basically, its a compression member as the load acts on columns longitudinal axis. The bending moment could occur because of wind, earthquake or accidental masses. RCC Column transfers the load of the structure of slab beams on top to below, and at last, the load is transferred to the soil. RCC Columns location ought to be specified such that it hides within the walls in partially or totally.

Types of RCC Columns Based on:-

Shapes

- Circular for exposed outside (Provides good architectural view and design)

- Square or rectangular traditionally for any kind of structure

Length

- Short column – if L/B<=12

- Long column – if L/B > twelve

Where L is that the height of the column, B is the width.

If the ground height is close to three meters or ten feet, the L/B quantitative ratio remains less than twelve. Thus in most cases, the short column is placed. Just in case wherever the height of the floor is above three m or ten feet, we’d examine L/B quantitative relation, thus the result could also be a long or short column. Generally, on a long column additional forces are generated more, thus ought to be designed fastidiously.

Moments

- Biaxial column: Designed for axial load and moment in two directions

- Uniaxial columns: Designed for axial load and moment in one direction

In most corners of buildings, the columns are mostly biaxial. The side columns are mostly uniaxial. Internal columns can be of any of these two types.

Construction of RCC Columns

Steps involving Construction of RCC columns:

- Column layout work

- Column reinforcement work

- Column formwork

- Pouring of concrete

Column layout work

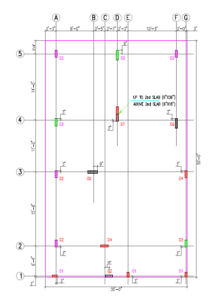

- In this stage, the situation of columns is determined realistically in the field. It’s done by birthing rope in keeping with grids shown within the column-making drawing below.

- In the drawing, column locations are shown associated with grid-line with dimensions. Realistically, in-field, ropes are our grid-lines. Thus, we tend to place columns associated with rope-line by calculating dimensions shown within the drawing.

Column marking at the construction site

Column Reinforcement

Column reinforcement works desires following list on site:

- Check for the diameter and also ensure the numbers of vertical bars

- Spacing between vertical bars

- Check Development length that depends on the diameter of the bar

- Lapping in alternate bars ought to return at the same height.

- Lapping mustn’t return within beam or block.

- Lapping ought to be at l/3 or 2l/3 of the column as per structural notes

- Spacing between the stirrups should be considered as per the drawing

- The hook ought to be bent properly at right angles.

- Check the stirrups corner. The vertical bar ought to return at the right angle fringe of stirrup properly certain with binding wire.

Steel Reinforcement of Column at web site edge

Column Lapping

The purpose behind column lapping is to retain the continuation of the bars to firmly transmit the load from one bar to a different bar.

Lapping Zone

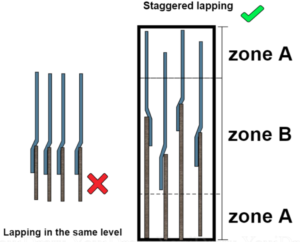

When providing lapping in the column, all the rebars ought to be lapped in zone-B as shown in the drawing above. The highest and bottom portion of the column, i.e. zone-A ( L/4 length ) ought to be avoided as there’ll be the most moment within this zone because of lateral forces engaged on the column.

Staggered Bars

All the lapped bars ought to be staggered among zone B as shown above. In any case, no more than fifty per cent of rebars could be lapped within the same level. If all the column bars square measure lapped at identical level, it ends up in failure of the column.

Stirrup Spacing

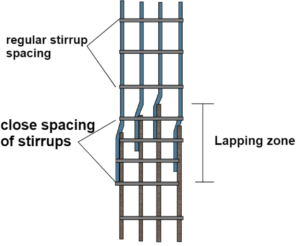

The spacing of the stirrups within the lapping zone ought to be minimal compared to the regular column c/c stirrup spacing.

Suppose the designed standard spacing for the stirrup is 175 c/c, then the spacing of stirrups within the imbrication zone could be a 150 c/c or 125 c/c as in keeping with the design of the column

Rebar placing

When we tie the rebars within the lapping zone, the joggled part of the bar ought to be placed over the inner surface of the lowest bar (refer to the drawing above ) to urge a consistent clear cover from the concrete surface.

If you tie the joggled portion of the rebar over the outer surface of the lowest bar, then the lapping zone would invade the concrete cover space provided for the bars.

Column Reinforcement Space

The reinforcement decreases when the column goes up as a result of the load engaged on the column decreases. Therefore the reinforcement of the column on the ground floor is mostly higher compared to higher levels. Therefore it’s not needed to use an identical reinforcement from the bottom to the top of the building.

RCC Column Formwork

Columns carry the load of structure and therefore they’re vital. It’s vital to align them for uprightness in order that load is transmitted properly. The column shuttering ought to be sturdy enough to bear the pressure of fresh and wet concrete and stay in position throughout concreting.

Some tips on column shuttering

- To hold the concrete shuttering firmly in situ and for correct alignment, a concrete pad known as a starter is forged before fixing the shuttering. The thickness is forty-five millimetre to sixty millimetre and dimensions square measure exactly identical to that of the dimensions of the planned column. The starter ought to be cured for 1-2 days or two in order that it’s strong enough to fix and hold the shuttering around it.

- The column box or shuttering for columns is formed of plyboard sheets or steel sheets made up of adequate stiffeners.

- A thin film of oil or grease ought to be applied to the inner surface of the shuttering to facilitate straightforward removal of the column when the concrete hardens.

- Shuttering ought to be properly aligned to its uprightness and diagonals to be checked to make sure the accuracy in dimensions.

- Formwork should be totally supported with props size before running the concrete in order that it doesn’t move horizontally or vertically throughout concreting.

- The gaps close to the shuttered joints ought to be sealed with plaster or a bit of wood to forestall any leakage.

- An appropriate area is to be provided within the inner face of the shutter and reinforcement by fixing covering blocks of 40mm.

- It is desirable to get rid of shutters in twenty-four hrs. of casting. They mustn’t be removed before sixteen hours.

- The removal of shutters should be done gently while not jerking in order that the edges of columns aren’t broken.

- Care ought to be taken relating to fixing and supporting column shuttering to avoid movement throughout concreting.

- Diagonals of the shuttering to be checked to make sure dimensional accuracy.

Concreting of RCC Column

Concreting of Associate in Nursing RCC column is done

- Manually

- With the assistance of a machine or pump

Manual Concreting of RCC Column

Concreting of RCC Column using Pump

Following points to be followed for RCC Column throughout and when concreting:

- Machine combine concrete is preferred for lesser quantities. For larger amounts ready mix concrete or RMC is ordered.

- Approval of putting concrete whether or not by pump or manually should be taken from the customer.

- Concrete ought to be poured up slab bottom, the remaining column gets concreted throughout the pouring of block & beam.

- Mechanical vibrator to be mandatorily utilized in the column however, excess vibration will cause segregation. Every layer ought to be totally compacted.

- The height of running concrete mustn’t exceed 1.5 meters

- Construction joints ought to be avoided within the column.

- Proper covers, as per structural drawings to be maintained.

- After the running of concrete and moving it with the assistance of a vibrator the horizontal and uprightness of the column to be checked.

Checking the spatial relation and uprightness of RCC Column

Curing

Wet coverings

This methodology is employed for column footings and therefore the bottom surface of slabs, wherever ponding isn’t attainable. Impervious coverings like bagging luggage/hessian are needed to hide the concrete. These membranes are sprayed with water to stay the concrete damp.

Good Practices at the site

- On the site, it’s an honest application to raise the column rebars up to 7feet before the slab casting. Adequate lapping is provided for the higher floors by following this.

- A separate column system ought to be provided for the elevator in order that the elevator load is safely transferred to the column.

RCC Column and shaft Reinforcement before Concreting

- After column box fixing and levelling the concrete cowl blocks square measure tied to column rebars to make sure a column cover (space between outer edge of column column and rebar) of 40mm.

RCC Column and shaft after Concreting

It is a foundational activity that is crucial for any construction activity. It is important to get advice from experts who can guide you through the entire process. Contact Samruddhi today for your every construction-related needs. We provide detailed and in-depth guidance and construction services. Our experts will take care of all your concerns.

Call us today!

Archives

Categories

- No categories